2.2

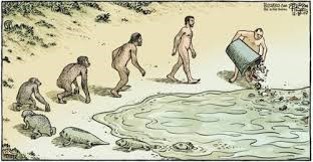

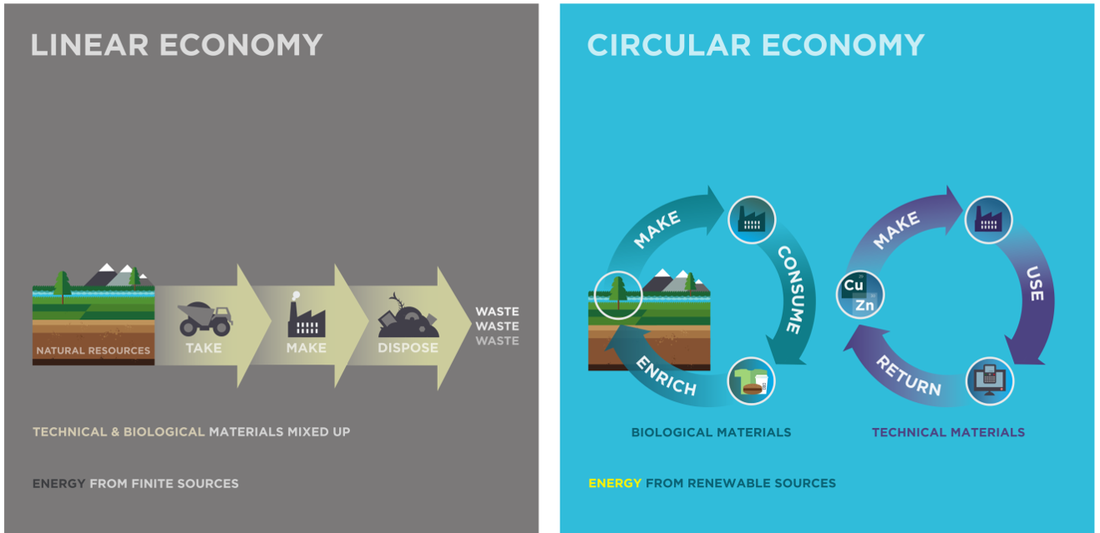

The abundance of resources and raw materials in the industrial age led to the development of a throwaway society, and as resources run out, the many facets of sustainability become a more important focus for designers.

The result of the throwaway society is large amounts of materials found in landfill, which can be considered as a new source to mine resources from.

The exploration of possible solutions to eliminate waste in our society has given rise to ideas developed as part of the circular economy. By redesigning products and processes, the waste from one product can become the raw material of another.

The abundance of resources and raw materials in the industrial age led to the development of a throwaway society, and as resources run out, the many facets of sustainability become a more important focus for designers. The result of the throwaway society is large amounts of materials found in landfill, which can be considered as a new source to mine resources from.

Designers design specifically for optimum use of existing manufacturing capability.

Design for manufacture or 'Manufacturability' concerns the cost and difficulty of making the product. At a simple level manufacturability, design for manufacture (DFM) at a part level, involves detail such as ensuring that where a pin is to be assembled into a hole that is only slightly larger in diameter, then it is much easier if the end of the pin or the entry to the hole (or both) are chamfered or finished with a radius.

"Changes to design and/or production process can result in delays, and possibly high costs to modify tooling and equipment. We avoided these penalties by concentrating our efforts on design for manufacture/assembly activities, which meant that potential issues were resolved at the Paper stage." Snowbone designers.

http://www.manufacturinginstitute.co.uk/news.asp?PageId=6&article=72&pos=0&cat=0&ind=0

"Changes to design and/or production process can result in delays, and possibly high costs to modify tooling and equipment. We avoided these penalties by concentrating our efforts on design for manufacture/assembly activities, which meant that potential issues were resolved at the Paper stage." Snowbone designers.

http://www.manufacturinginstitute.co.uk/news.asp?PageId=6&article=72&pos=0&cat=0&ind=0

|

|

|

Design for manufacture:

Can be conveniently split into design for materials, design for process and design for assembly.

Design for materials:

Designing in relation to materials during processing, rather than designing for the final desired properties of the end product in use.

Design for process:

Designing to enable the product to be manufactured using a specific manufacturing process, for example, injection moulding.

Design for assembly:

Designing taking account of assembly at various levels, for example, component to component, components into sub-assemblies and subassemblies into complete products.

Can be conveniently split into design for materials, design for process and design for assembly.

Design for materials:

Designing in relation to materials during processing, rather than designing for the final desired properties of the end product in use.

Design for process:

Designing to enable the product to be manufactured using a specific manufacturing process, for example, injection moulding.

Design for assembly:

Designing taking account of assembly at various levels, for example, component to component, components into sub-assemblies and subassemblies into complete products.

|

|

|

|

|

Reuse is using an item more than once. This includes conventional reuse where the item is used again for the same function, and new-life reuse where it is used for a new function.

Reuse can have financial and environmental benefits, either of which can be the main motivation for it. The financial motivation historically did, and in the developing world still does, lead to very high levels of reuse, but rising wages and consequent consumer demand for the convenience of disposable products made the reuse of low value items such as packaging uneconomic in richer countries, leading to the demise of many reuse schemes. Current environmental awareness is gradually changing attitudes and regulations, such as the new packaging regulations, are gradually beginning to reverse the situation. |

|

The classic example of conventional reuse is the doorstep delivery of milk in reusable bottles; other examples include the retreading of tyres and the use of plastic delivery trays (transit packing) in place of cardboard cartons, the refilling toner cartridges in photocopiers and printers, designing computers so that the central processing unit can be upgraded, using an ice-cream container as a toy box. http://en.wikipedia.org/wiki/Reuse http://www.coupons.com/thegoodstuff/14-brilliant-ways-to-reuse-old-light-bulbs/ |

Repair

Is the reconstruction or renewal of any part of an existing structure or device.

Is the reconstruction or renewal of any part of an existing structure or device.

|

Maintenance management or Maintenance, ('MRO), is fixing any sort of mechanical or electrical device should it become out of order or broken (repair) as well as performing the routine actions which keep the device in working order (maintenance) or prevent trouble from arising (preventive maintenance).

The European Federation of National Maintenance Societies defines maintenance as: All actions which have the objective of retaining or restoring an item in or to a state in which it can perform it's required function. The actions include the combination of all technical and corresponding administrative, managerial, and supervision actions. http://en.wikipedia.org/wiki/Repair_and_maintenance |

|

Recondition

Reconditioning is rebuilding a product so that it is in an “as new” condition, by repairing it, cleaning it, or replacing parts. Contexts include car engines, tyres or refurbished electronics. Reconditioning; To restore to good condition, especially by repairing, renovating, or rebuilding. http://www.thefreedictionary.com/reconditioning |

Recycling is the reprocessing of materials into new products. Recycling generally prevents the waste of potentially useful materials, reduces the consumption of raw materials and reduces energy usage, and hence greenhouse gas emissions, compared to virgin production. Recycling is a key concept of modern waste management and is the third component of the waste hierarchy.

Recyclable materials, also called "recyclables", may originate from a wide range of sources including the home and industry. They include glass, paper, aluminium, asphalt, iron, textiles and plastics. Biodegradable waste, such as food waste or garden waste, is also recyclable with the assistance of micro-organisms through composting or anaerobic digestion.

The term recycling does not generally include reuse, in which existing items are used for a new purpose.

http://en.wikipedia.org/wiki/Recycling

Recyclable materials, also called "recyclables", may originate from a wide range of sources including the home and industry. They include glass, paper, aluminium, asphalt, iron, textiles and plastics. Biodegradable waste, such as food waste or garden waste, is also recyclable with the assistance of micro-organisms through composting or anaerobic digestion.

The term recycling does not generally include reuse, in which existing items are used for a new purpose.

http://en.wikipedia.org/wiki/Recycling

Some materials are easier and more economical to recycle than others and some cannot currently be recycled at all. Designers can encourage recycling by their choice of materials. Specific materials implies, for example, copper (not just metal), silica glass (not just glass) etc.

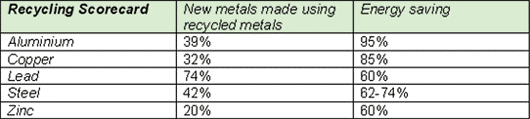

Metals recycling is a £4.5billion UK industry, processing ferrous and non ferrous metal scrap into vital secondary raw material for the smelting of new metals.. Worldwide, over 400 million tonnes of metal is recycled each year.

Virtually all metals can be recycled into high quality new metal. The process varies for different metals, but generally produces metals of equivalent quality. Thus, for example:

Virtually all metals can be recycled into high quality new metal. The process varies for different metals, but generally produces metals of equivalent quality. Thus, for example:

- Steelmaking using the electric arc furnace process uses scrap metal as the major raw material. This method is typically used for high quality tool steels and stainless steel. Smaller quantities of scrap can also be used in basic oxygen (blast furnace) steelmaking.

- Copper scrap is used by both primary and secondary producers, where processing methods include blast furnace, reverberatory furnace or electric arc furnace. In the latter, around 75-80 per cent raw material is scrap copper.

- Aluminium production uses a single production method - the Hall-Héroult Process. But virgin raw materials require temperatures of around 900 C, whilst scrap aluminium melts at around 660 C.

Metals recycling protects the environment and saves energy. Using secondary raw materials means less use of natural resources which would otherwise be needed to make new metal compounds – such as iron ore in steelmaking; nickel in stainless steel; or alumina and bauxite in aluminium smelting. There are also considerable savings in energy, and reduced CO2 emissions, in production methods using recycled materials.

http://www.recyclemetals.org/whatis.php

http://www.recyclemetals.org/whatis.php

|

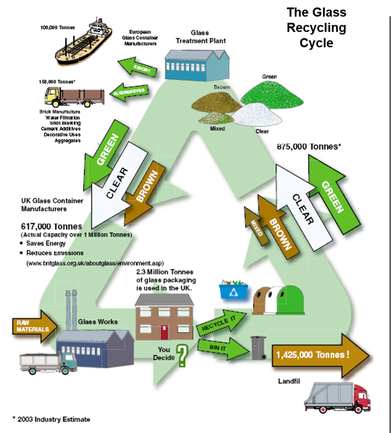

Glass

One of the many virtues of glass is that the material is theoretically "infinitely recyclable". Taking our bottles and jars to the glass banks is a way we can ALL make a positive contribution to the environment. It also takes less energy to recycle glass than to melt down the original raw materials. Despite the UK glass industry's pioneering commitment to recycling, the current rate achieved in the UK (35%) compares unfavourably with our European neighbours where recycling of 80-90 per cent has been achieved. http://www.britglass.org.uk/Education/Recycling.html |

|

|

|

Plastic

One of the most difficult wastes to recycle is mixed plastic, often used in wrappers and containers. Plastics manufacturers turn their own off cuts into granules that are melted down for reuse. They can also reuse any single, pure thermo plastic material - plastics such as polythene that are not chemically cross-linked. The British firm Meyer-Newman of Gwent recycles complete telephones into new ones. But mixed plastics have unpredictable properties and low structural strengths because the different plastics in the mixture are not bonded at a molecular level. So, it is difficult to make a material with good and predictable properties from mixed plastics waste.

http://environment.newscientist.com/article/new-technology-.html

One of the most difficult wastes to recycle is mixed plastic, often used in wrappers and containers. Plastics manufacturers turn their own off cuts into granules that are melted down for reuse. They can also reuse any single, pure thermo plastic material - plastics such as polythene that are not chemically cross-linked. The British firm Meyer-Newman of Gwent recycles complete telephones into new ones. But mixed plastics have unpredictable properties and low structural strengths because the different plastics in the mixture are not bonded at a molecular level. So, it is difficult to make a material with good and predictable properties from mixed plastics waste.

http://environment.newscientist.com/article/new-technology-.html

|

The compatibiliser

This is an octopus-like molecule in which each 'arm' represents a section of a different polymer, that in turn is characteristic of a different plastic. Stirred into a mixture of molten plastics, each arm of the octopus grabs and reacts chemically with a molecule of one polymer in the mixture. The result is an alloy rather than a mixture. It is strong because of intra-molecular bonding and has highly predictable properties, so it is potentially reusable. |

|

|

|

The vehicles recycling industry is keen to recycle more plastics. Despite the environmental benefits, they fear that the steady increase in the use of unreclaimable plastics will soon make it uneconomic to recover vehicles for the metals they contain. Some car manufacturers, such as BMW and Mercedes, are now designing products and requesting components that are easier to recycle; for example, car bumpers made from one material instead of up to seven.

http://environment.newscientist.com/article/mg12717333.400

http://environment.newscientist.com/article/mg12717333.400

|

Designing for dis-assembly

Designing a product so that when it becomes obsolete it can easily and economically be taken apart, the components reused or repaired, and the materials recycled. Designing products in order to minimise their impact on the environment is becoming increasingly important. Many designers are beginning to recognise this fact and are therefore demanding tools and techniques which enable them to design more responsibly. One technique which can be used is Design for Disassembly - this enables the product and its parts to be easily reused, re-manufactured or recycled at end of life. http://www.co-design.co.uk/design.htm |

Wilkhahn chairs are designed to be taken a part and upgraded.

|

|

Designing components made from one material. Using thermoplastic adhesives that lose their properties when reheated. Designing snap fittings instead of welding and gluing.

FROG design recently created the "Chill" chair for Landscape Forms. This rotationally molded plastic lounge is a refreshing new look from typical wood and steel outdoor furnishings. Although its designed for outdoor spaces, "Chill" would be a fabulous edition to the porch or living room. http://www.specbookproblog.com/green_design/index.html |

|

"Cellphones are the most valuable form of e-waste. Each one contains about a dollar’s worth of precious metals, mostly gold. And while single phones house far less hazardous material than a computer — an old, clunky monitor can incorporate seven pounds of lead — their cumulative presence is staggering. http://www.textually.org/textually/archives/2008/01/018650.htm |

Re-engineer

A re-engineered product has been significantly redesigned, with improved engineering, from its original form.

In may: use raw materials that were meant another product or manufacturing process, use environmentally friendly materials, recycle some of the original components, improve performance.

•The Dyson Ball Vacuum cleaner has been re-emgineered.

•Tacoma re-engineered to be off-road

A re-engineered product has been significantly redesigned, with improved engineering, from its original form.

In may: use raw materials that were meant another product or manufacturing process, use environmentally friendly materials, recycle some of the original components, improve performance.

•The Dyson Ball Vacuum cleaner has been re-emgineered.

•Tacoma re-engineered to be off-road

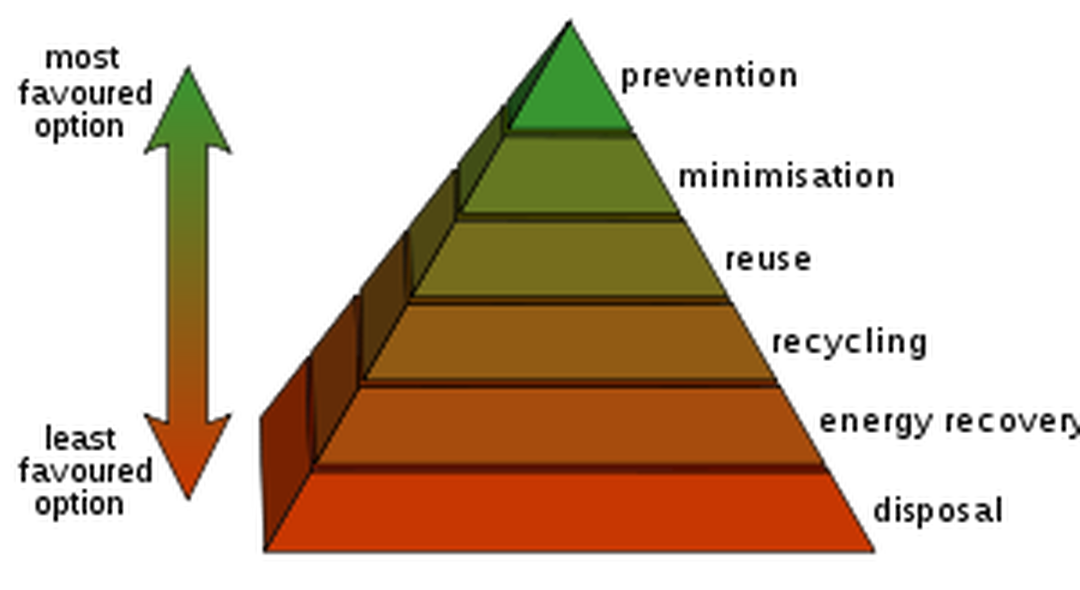

Waste-mitigation strategies

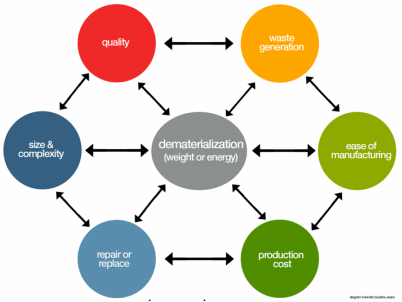

Designing out waste and designing for closed-loop recycling will be more important as resources become scarcer and waste becomes more expensive. Therefore, developing products for product recovery and dematerialization will become an essential element of innovation.

Waste minimization is a process of elimination that involves reducing the amount of waste produced in society and helps eliminate the generation of harmful and persistent wastes, supporting the efforts to promote a more sustainable society.[1] Waste minimisation involves redesigning products and/or changing societal patterns, concerning consumption and production, of waste generation, to prevent the creation of waste.

The most environmentally resourceful, economically efficient, and cost effective way to manage waste is to not have to address the problem in the first place. Waste minimisation should be seen as a primary focus for most waste management strategies. Proper waste management can require a significant amount of time and resources; therefore, it is important to understand the benefits of waste minimisation and how it can be implemented in all sectors of the economy, in an effective, safe and sustainable manner.

Waste management focuses on processing waste after it is created, concentrating on re-use, recycling and waste-to-energy conversion rather than eliminating the creation of waste in the initial phases of production. Waste minimisation involves efforts to minimize resource and energy use during manufacture. For the same commercial output, usually the less materials are used, the less waste is produced. Waste minimisation usually requires knowledge of the production process, cradle to grave analysis (the tracking of materials from their extraction to their return to earth) and detailed knowledge of the composition of the waste.

Designing out waste and designing for closed-loop recycling will be more important as resources become scarcer and waste becomes more expensive. Therefore, developing products for product recovery and dematerialization will become an essential element of innovation.

Waste minimization is a process of elimination that involves reducing the amount of waste produced in society and helps eliminate the generation of harmful and persistent wastes, supporting the efforts to promote a more sustainable society.[1] Waste minimisation involves redesigning products and/or changing societal patterns, concerning consumption and production, of waste generation, to prevent the creation of waste.

The most environmentally resourceful, economically efficient, and cost effective way to manage waste is to not have to address the problem in the first place. Waste minimisation should be seen as a primary focus for most waste management strategies. Proper waste management can require a significant amount of time and resources; therefore, it is important to understand the benefits of waste minimisation and how it can be implemented in all sectors of the economy, in an effective, safe and sustainable manner.

Waste management focuses on processing waste after it is created, concentrating on re-use, recycling and waste-to-energy conversion rather than eliminating the creation of waste in the initial phases of production. Waste minimisation involves efforts to minimize resource and energy use during manufacture. For the same commercial output, usually the less materials are used, the less waste is produced. Waste minimisation usually requires knowledge of the production process, cradle to grave analysis (the tracking of materials from their extraction to their return to earth) and detailed knowledge of the composition of the waste.

Waste management is all those activities and action required to manage waste from its inception to its final disposal. This includes amongst other things, collection, transport, treatment and disposal of waste together with monitoring and regulation. It also encompasses the legal and regulatory framework the relates to waste management encompassing guidance on recycling etc.

|

The dematerialization of a product literally means less, or better yet, no material is used to deliver the same level of functionality to the user. Sharing, borrowing and the organization of group services that facilitate and cater for communities needs could alleviate the requirement of ownership of many products. In economics, dematerialization refers to the absolute or relative reduction in the quantity of materials required to serve economic functions in society. In common terms, dematerialization means doing more with less. |

|

|

|