2.4

|

Clean technology (clean tech) is a general term used to describe products, processes or services that reduce waste and require as few non-renewable resources as possible.

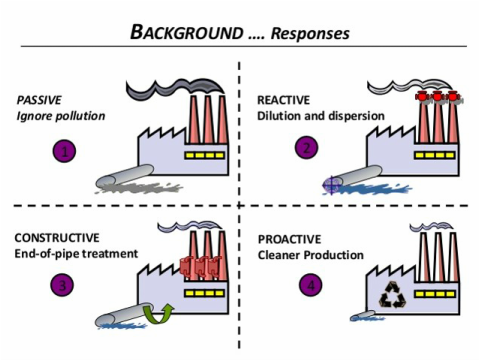

The Clean Technology Trade Alliance, a global initiative to drive the expansion of clean tech, defines it as: "A broad base of processes, practices and tools, in any industry that supports a sustainable business approach, including but not limited to: pollution control, resource reduction and management, end of life strategy, waste reduction, energy efficiency, carbon mitigation and profitability" The legislation for reducing pollution often focuses on the output and therefore, the end of pipe technologies. |

The drivers for cleaning up manufacturing can be divided up into three basic groups:

1.Social

2.Political

3.Economical

1.Social

2.Political

3.Economical

International legislation and targets for reducing pollution and waste

In Europe 16 tonnes of material is used per person per year, of which 6 tonnes become waste.

Just in terms of household waste alone, each person in Europe is currently producing, on average, half of tonne of such waste. Only 40 % of it is reused or recycled and in some countries more than 80% still goes to landfill.

If we re-manufacture, reuse and recycle, and if one industry's waste becomes another's raw material, we can move to a more circular economy where waste is eliminated and resources are used in an efficient and sustainable way.

Turning waste into a resource is one key to a circular economy. The objectives and targets set in European legislation have been key drivers to improve waste management, stimulate innovation in recycling, limit the use of landfilling, and create incentives to change consumer behaviour.

In Europe 16 tonnes of material is used per person per year, of which 6 tonnes become waste.

Just in terms of household waste alone, each person in Europe is currently producing, on average, half of tonne of such waste. Only 40 % of it is reused or recycled and in some countries more than 80% still goes to landfill.

If we re-manufacture, reuse and recycle, and if one industry's waste becomes another's raw material, we can move to a more circular economy where waste is eliminated and resources are used in an efficient and sustainable way.

Turning waste into a resource is one key to a circular economy. The objectives and targets set in European legislation have been key drivers to improve waste management, stimulate innovation in recycling, limit the use of landfilling, and create incentives to change consumer behaviour.

Clean technology

While there is no standard definition of "clean technology," it has been described as "a diverse range of products, services, and processes that harness renewable materials and energy sources, dramatically reduce the use of natural resources, and cut or eliminate emissions and wastes." [...] "Clean technologies are competitive with, if not superior to, their conventional counterparts. Many also offer significant additional benefits, notably their ability to improve the lives of those in both developed and developing countries"

[http://cleanedge.com/about]

Clean technology includes recycling, renewable energy (wind power, solar power, biomass, hydropower, biofuels, etc.), information technology, green transportation, electric motors, green chemistry, lighting, Greywater, and many other appliances that are now more energy efficient. It is a means to create electricity and fuels, with a smaller environmental footprint and minimise pollution. To make green buildings, transport and infrastructure both more energy efficient and environmentally benign.

[https://en.wikipedia.org/wiki/Clean_technology]

Drivers for Clean Technology

Its origin is the increased consumer, regulatory, and industry interest in clean forms of energy generation—specifically, perhaps, the rise in awareness of global warming, climate change, and the impact on the natural environment from the burning of fossil fuels.

[https://en.wikipedia.org/wiki/Clean_technology]

Drivers for cleaning up manufacturing include promoting positive impacts; ensuring neutral impact or minimising negative impacts through conserving natural resources; reducing pollution and use of energy; reducing wastage of energy and resources.

While there is no standard definition of "clean technology," it has been described as "a diverse range of products, services, and processes that harness renewable materials and energy sources, dramatically reduce the use of natural resources, and cut or eliminate emissions and wastes." [...] "Clean technologies are competitive with, if not superior to, their conventional counterparts. Many also offer significant additional benefits, notably their ability to improve the lives of those in both developed and developing countries"

[http://cleanedge.com/about]

Clean technology includes recycling, renewable energy (wind power, solar power, biomass, hydropower, biofuels, etc.), information technology, green transportation, electric motors, green chemistry, lighting, Greywater, and many other appliances that are now more energy efficient. It is a means to create electricity and fuels, with a smaller environmental footprint and minimise pollution. To make green buildings, transport and infrastructure both more energy efficient and environmentally benign.

[https://en.wikipedia.org/wiki/Clean_technology]

Drivers for Clean Technology

Its origin is the increased consumer, regulatory, and industry interest in clean forms of energy generation—specifically, perhaps, the rise in awareness of global warming, climate change, and the impact on the natural environment from the burning of fossil fuels.

[https://en.wikipedia.org/wiki/Clean_technology]

Drivers for cleaning up manufacturing include promoting positive impacts; ensuring neutral impact or minimising negative impacts through conserving natural resources; reducing pollution and use of energy; reducing wastage of energy and resources.

|

Example:

Apple is cleaning up its manufacturing operations in China to reduce the air pollution caused by the factories that have assembled hundreds of millions of iPhones and iPads during the past eight years. The world's most valuable company is working with its Chinese suppliers to eventually produce 2.2 gigawatts of solar power and other renewable energy. The commitment represents Apple's latest attempt to prevent the popularity of its devices and digital services from increasing the carbon emissions that are widely believed to changing the Earth's climate. Apple Inc. estimates 20 million metric tons of greenhouse gas pollution will be avoided as more of its suppliers rely on renewable energy between now and 2020. That's like having four million fewer cars on the road for a year. Panels capable of generating about 200 megawatts of solar power will be financed by Apple in the northern, southern and eastern regions of China, where many of its suppliers are located. The Cupertino, California, company is teaming up with its Chinese suppliers to build the capacity for the remaining 2 gigawatts of renewable energy, which will be a mix of solar, wind and hydroelectric power. [http://www.ctvnews.ca/sci-tech/apple-to-clean-up-manufacturing-operations-in-china-to-reduce-air-pollution-1.2621677] Apple also announced last week that it had bought up 36,000 acres of forest in the east of the US, which it will use to make sure that the paper in its packaging is renewable. [http://www.independent.co.uk/life-style/gadgets-and-tech/news/earth-day-apple-turns-stores-green-pledges-to-clean-up-manufacturing-processes-10195296.html] |

|

End of pipe techniques

Definition:

Methods used to remove already formed contaminants from a stream of air, water, waste, product or similar. These techniques are called 'end-of-pipe' as they are normally implemented as a last stage of a process before the stream is disposed of or delivered.

Technologies such as scrubbers on smokestacks and catalytic convertors on automobile tailpipes that reduce emissions of pollutants after they have formed.

In economic terms, it is cheaper to prevent any potential environmental damage and deal with the issues at the source rather than try to mitigate their effects after the offending emissions, waste or inefficiencies have already occurred.

These pollutant reducing measures are often less dramatic and smaller in scale than their end of pipe counterparts.

Definition:

Methods used to remove already formed contaminants from a stream of air, water, waste, product or similar. These techniques are called 'end-of-pipe' as they are normally implemented as a last stage of a process before the stream is disposed of or delivered.

Technologies such as scrubbers on smokestacks and catalytic convertors on automobile tailpipes that reduce emissions of pollutants after they have formed.

In economic terms, it is cheaper to prevent any potential environmental damage and deal with the issues at the source rather than try to mitigate their effects after the offending emissions, waste or inefficiencies have already occurred.

These pollutant reducing measures are often less dramatic and smaller in scale than their end of pipe counterparts.

|

End of pipe technology

|

Cleaner production

|

They gave the name end-of-pipe (EOP) to the method that was being urged by lazy polluters who wanted to make no basic changes.

Imagine a pipe with chemical waste that is discharging pollution into a river. Do you add a treatment box onto the end of the pipe and try to mitigate the worst features of what is pouring out, such as filtering it or treating it with additional chemicals.

Or...

do you go back to the process that produces that pollution and research why it is being produced, then change the process so that the discharge no longer occurs?

|

Advantages and dis-advantages of incremental solutions

|

Advantages and dis-advantages of radical solutions

|